In the quest for greener trucks, Battle Motors and Curbtender have collaborated to create a zero-emissions truck for refuse collection pairing the Curbtender Quantum MD rear loader with the Battle Motors fully electric LNT chassis.

Quantum MD is uniquely suited for an EV application because its unique packing mechanism utilizes a patented “swing panel” tailgate weighing thousands of pounds less than a conventional side/sweep tailgate while providing better weight distribution.

In this article, Battle Motors has examined the features and specifications of this innovative electric vehicle and gathered operational testing to analyze its efficiency on extended routes. This article also explors the battery system, powertrain, and unique design of the Quantum MD electric rear loader.

GOAL

Battle Motors’ objective was to acquire real-time data regarding route information and vehicle performance under demanding conditions.

SUMMARY

The organization leveraged the capabilities of the Battle Motor’s proprietary RevolutionOS™ (RevOS™) platform data from the routes ran in Tampa, Florida on September 18, and September 20, 2023, with a temperature range between 75 – 96 degrees Fahrenheit.

APPLICATION

Residential Refuse

OVERVIEW

FCC Environmental Services and Battle Motors conducted a rigorous operational test of the Battle Motors Battery Electric Vehicle (BEV) LNT Curbtender RL equipped with a 240kWh battery pack. This assessment took place within both the urban and rural areas of Hillsborough County, subjecting the vehicle to the demands of a typical workday.

Throughout an 8-hour day, during which temperatures reached a maximum of 96 degrees Fahrenheit, the Battle Motors BEV conducted residential refuse pickups and navigated the narrow streets and alleys in Hillsborough County with notable agility. The ability to remotely monitor the truck’s performance in real-time proved to be significant during the testing phase, as it provided kWh usage data.

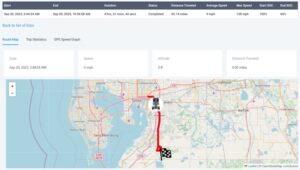

RevOS™ captured key performance metrics of the vehicle, including comprehensive route data. This robust data collection and analysis process formed the foundation for the evaluation of Battle Motors BEV’s performance within the urban and rural environments of Hillsborough County.

MATERIALS

BEV (Battery Electric Vehicle) LNT (Low Narrow Tilt) – Curbtender 11CY QuantumMD Rear Loader – Weight (empty) is 25,980 lbs.

TRUCK DATA AT HIGH LEVEL

The information provided pertains to data collected from a single truck over one day. It is important to clarify that these data collections did not occur on consecutive days.

| Maximum Distance Traveled in One Day | 90.2 miles |

| Max Speed | 70 MPH |

| Max Battery Required Recommendation | 240 kWh |

| Type of pick up – Residential or Commercial | Residential |

| Cans / Stops | 600* |

*An estimate of cans collected on the longest day.

DATA REVIEW

The data presented was gathered during a single-day route. Throughout an 8-hour workday, the truck covered 90.2 miles, encompassing back-road and freeway driving. Notably, the lowest point the “EV (Electric Vehicle) state of charge” (battery percentage) reached was 37%. Chart 1 (below) provides a top-level overview of select data obtained through RevOS installed in the truck, which combines data from the truck’s CAN system, chassis, body, and GPS.

A selection of routes was examined and collected by the FCC truck during the data harvesting process. Subsequently, Battle Motors processed the data acquired from the REVOS system and transferred it into the Battle Motors electric reporting tools.

This data includes:

- Location

- Latitude

- Longitude

- Altitude

- Speed

- Bearing

- Route Driven

- Total Vehicle Distance

SUMMARY OF DATA COLLECTED:

Below is a sample data collection of location, time, current speed, altitude, and distance traveled in the trip.

BEV EFFICIENCY REVIEW

During the 90.2-mile, 8-hour run, the truck achieved an average of 1.12 kWh per mile, demonstrating strong electric performance for demanding routes. The driver extended the route another 150 cans because he had 75% battery life left at the last can. He was also able to maneuver narrow streets much more efficiently by performing U-turns, which he otherwise could not perform in an ICE refuse truck.

In summary, this demonstrates that a Zero Emissions Vehicle (ZEV) can successfully complete extended routes, all while operating at a significantly lower decibel level compared to its ICE counterpart.

DUMP SCALES (12 HOURS)

| Total full | 31,630 lbs. |

| Total after dump | 26,130 lbs. |

| Payload | 5,500 lbs |

EV STATE OF CHARGE (SOC) OVER TIME

September 18 – September 20, 2023

BATTERY RECOMMENDATION

Battle Motors offers two primary battery usage configurations for its trucks, catering to a broad range of usage scenarios in the market. These configuration choices were developed in response to the increasing market demand for greater diversity in usage.

Currently, the following pack configurations are available in 240 kWh and 400 kWh.

| Truck | kWh* |

| FCC Truck 1 | 240 |

CONCLUSION

As demonstrated in the chart above, the battery system in the vehicle had not yet completed State of Charge (SOC) reconfiguration, which explains the starting charge of 89% and faster discharge rate. SOC reconfiguration is needed on newly assembled electric vehicles so that the Battery Management System (BMS) may learn the bounds of operation for the system. Searching for a charger added another 22 miles to the route and only resulted in a 2% additional charge. This was because the public charger used was a 6.7kWh charger plugged in for a 45-minute lunch period. With a full state of charge and without having to search for a public charger, it is assumed that the driver could easily complete the full route in a day while maintaining a legal payload of up to 5 tons.

The driver noted that the truck was vastly more maneuverable than its ICE counterparts, as well as much smoother to operate. He described the LNT BEV as feeling more like a car than a heavy-duty truck. An analysis of the route data revealed that the 240-kWh capacity truck efficiently performed a modified route, meeting customer expectations for FCC in Hillsborough County.

As the truck continues its tenure with FCC, further insights and advancements will elevate the potential of continued innovative solutions.

BATTERY SPECIFICATIONS

| Battery Cell Chemistry | LFP |

| Operational Temperature Range | -35°C – 60°C |

| Rated Energy | 240kWh |

| Maximum Continuous Charge Current | 346A |

| Maximum Continuous Charge Power | 240kW |

| Peak Charge Power | 480kW |

| Maximum Continuous Discharge Power | 240kW |

| Peak Discharge Power | 556kW |

| Thermal Management | Cooling: Liquid Cooling Heating: Heating film |

| Operational Voltage Range | 540V – 750V |

POWERTRAIN SPECIFICATIONS

| Drive Motor | BorgWarner Cascadia Motion HVH410-150 |

| Drive Inverter | BorgWarner Cascadia Motion PM250 |

| Peak Torque | 2050Nm |

| Peak Power | 300kW |

| Maximum Motor Speed | 6,000RPM |

| Transmission | Direct Drive |

| Cooling Medium | Dexron VI |

| Motor Assembly Mass (Motor Only) | 140kg |

| Maximum Efficiency | 95% |

The BEV Rear Loader Curbtender is a revolutionary refuse truck that promotes sustainability. It competes with traditional trucks in refuse collection, thanks to its innovative design, impressive specifications, and efficient performance. Operational testing with FCC Environmental Services and Battle Motors provided valuable insights into its capabilities. Contact our team to learn more about this sustainable transportation solution for residential refuse applications.